Search

CN

Call Me

+86-21-50125451

Email

tinali02@126.com

In the complex hydraulic systems of construction machinery and industrial manufacturing, the rapid connection and stable transmission of multiple pipelines are core issues determining operational efficiency and safety. The Hydraulic Multi-Coupling Plate (also known as a Multi-Coupler or Multi-Connection System) has become a revolutionary component replacing traditional single-coupling operations. Its success stems from its ingenious integrated working principle—organically fusing synchronized control, sealing protection, and safety adaptation. This not only solves the cumbersome problem of multi-line docking but also builds a solid defense line for stable system operation, injecting strong momentum for efficient production across various industries.

Integrated Synchronized Control

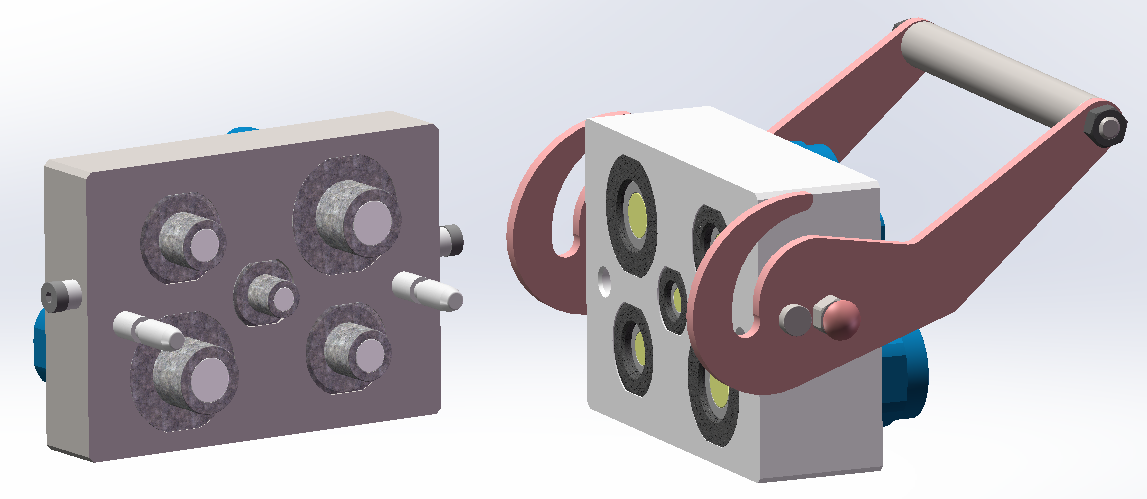

The Core LogicIntegrated synchronized control is the logic behind the multi-coupling plate’s disruption of traditional operation modes. Unlike single couplings that require time-consuming, one-by-one connection, the multi-coupling plate utilizes a modular design to integrate multiple hydraulic, pneumatic, and even electrical interfaces onto a single installation base. Internally, it is equipped with a linkage drive mechanism (lever-operated, pneumatic, or hydraulic). When the operator activates the control component, the linkage shaft synchronously drives the locking structures (such as steel ball locking sleeves or clamp-style components) of all interfaces. This achieves "one-key switching, global synchronization" for engaging or disengaging multiple lines simultaneously.

From a principle standpoint, this design eliminates the sequence confusion often seen in single-coupling operations. Taking heavy equipment attachment switching as an example, traditional multi-line docking takes over 10 minutes. With the synchronized control of the multi-coupling plate, this is compressed to 2-3 minutes, boosting efficiency by over 70% and significantly reducing equipment downtime. Some high-end models also incorporate grouped control logic, driving internal valve groups via partitions to switch specific media transmission independently, balancing integrated convenience with operational flexibility for precise control in complex conditions.

Sealing and Pressure Balance

Key Support for StabilitySealing and pressure balance principles are crucial for the multi-coupling plate to ensure stable system operation. Based on the core structure of flat-face valves, the valve spool faces fit tightly during docking. Combined with specialized seals (FKM/Viton, NBR) that are oil, temperature, and corrosion-resistant, they form a multi-barrier seal. This fundamentally prevents the leakage of media such as hydraulic oil and compressed air, avoiding resource waste and environmental pollution while preventing power loss due to pressure drops.

Simultaneously, the multi-coupling plate features a built-in residual pressure elimination valve. Before docking, it automatically releases residual pressure within the pipeline to balance the pressure difference between the two ends. Even if the system is under a rated working pressure of 350 bar, effortless docking is achieved. This thoroughly resolves the pain points of traditional couplings, which are difficult to connect under pressure and prone to pressure surges. Upon disconnection, the valve spools of each interface automatically reset and close, achieving independent single-line sealing to effectively prevent fluid leakage and contaminant intrusion, thereby extending the overall service life of the hydraulic system.

Safety Locking and Standardized Adaptation

Reliability and UniversalitySafety locking and standardized adaptation principles endow the multi-coupling plate with both reliability and universality. Once docking is complete, the locking structure automatically secures the coupler body, working with a mechanical safety limit device to form double protection. This resists external forces such as vibration and collision during operation, eliminating safety accidents caused by accidental disconnection. Some models feature error-proofing guide pins, which, through precise dimensional positioning, only allow docking of couplings of the same specification and type, preventing misconnection risks by design.

Regarding adaptability, the multi-coupling plate strictly follows industry standards such as ISO 16028. Interface dimensions and thread specifications are unified, allowing interchangeability with standard products from international brands like Parker, CEJN, and Stucchi. Whether for new equipment integration or retrofitting old systems, it quickly adapts to existing pipelines without large-scale adjustments, significantly lowering parts procurement and maintenance costs. Furthermore, configurations can be customized from 3 to 18 lines based on working conditions, supporting combinations of different diameters and media types to adapt to diverse transmission scenarios like hydraulic oil, water-glycol, and compressed air, realizing the value of "one plate for multiple uses."

Kuaishi Solution: Kuaishi's PH Series Hydraulic Multi-Connectors are specifically designed for rapid, efficient, and leak-free multi-line connections in high-pressure hydraulic systems. They integrate the three major advantages of synchronized efficiency, sealing performance, and safety assurance. In the harsh, dusty environments of mining machinery, their sealing and anti-detachment principles ensure stable pipeline transmission; in the multi-circuit test systems of precision manufacturing, their grouped control principle enables precise operation and maintenance; and in the multi-functional operations of agricultural machinery, their standardized adaptation principle meets the demands of high-frequency switching.